I know this post is redundant but I'm hoping for some fresh hits from the wind power guys and I figure I'll do better if I move the buffet closer to the front door.

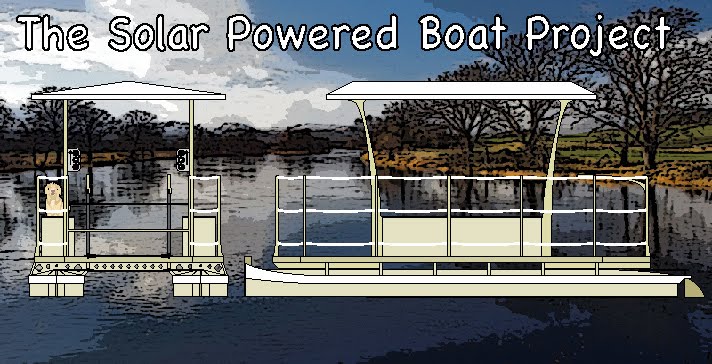

The craft is designed to be very light so that it will be easily propelled thru the water. I was a little too successful in my design in that the boat itself, stripped, will weigh less then 800 lb. (360kg).

It will need to weigh 2200 lb. (1000kg) loaded to draw enough water to keep the props at an effective depth.

This is a plus in that I could easily jump from a total of eight batteries to twelve and still have plenty of left over GVW for gear and supplies.

The negative side of the weight issue is that with around 170 square feet of deck and canopy, she could be flipped pretty easy by a strong gust of wind at just the wrong angle.

The Solar panels will articulate. The plan is to hinge them along the ridge of the canopy with some low-tech manual props at the sides of the canopy. There are two issues here:

The river physically runs east and west more often then it runs north/south.

Tilting the panels will give me an even bigger profile in the wind.

The system must to be split into two separate, isolated units.

If anything happens to fail while underway, I need to get the heck out of the shipping channel. There's no breaks on a commercial barge and they would roll over my little boat like a bus over a cheeseburger.

No way I'm putting my eggs or may ass in one basket.

I'm using inboard electric motors with fixed propeller shafts for several reasons:

Conventional electric trolling motors are not designed for full time primary drive or long term immersion.

I can buy two industrial grade DC motors, ESC's, a couple of batteries and a months supply of Guinness Extra Stout for what it would cost to buy just one "Torqueedo".

I can experiment with efficiency of the drive fairly cheaply.

Varying gear ratios between the motor and propeller shaft would only cost me a pulley and a belt, I can use Piranha Props which have interchangeable blades. This allows me to try different blade pitches without the cost of replacing 2 complete props.

Item last would be the wind turbines. I'll need to go with VAWT's.

The 'squirrel cage' will have a maximum diameter of 24" but they could be as tall as 6' with supports at the top.

With the VAWT's mounted in the 4 corners of the craft, they run serious risk of damage in the locks and at dock side.

They'll need to be removable.

I'm considering hard mounting the housing containing the stator and rotors to the craft and being able to lift the masts and fans out of the alternators when the need arises.

Sunday, November 15, 2009

I've started to research the turbines.

There's a LOT of information to wade thru.

The manufacture is something I can easily do,

...the design is another story.

The research and a couple of projects that came up late in the week kept me from posting the new drawings, they'll be up tonight.

The manufacture is something I can easily do,

...the design is another story.

The research and a couple of projects that came up late in the week kept me from posting the new drawings, they'll be up tonight.

Saturday, November 7, 2009

Seems like I only open my mouth...

...to change feet.

The Skipper of the Greenhorn I (who's also an EE) got me straightened out as far as what happens to the output of 12V wet cells when the power gets low.

Short version: my stooges switchboard is toast.

It's all good, all I'm out is the one sketch, I'm saving myself some hardware and the support crew is sleeping much better.

The "How to get electrocuted" in the last tag line didn't sit well.

I had planned on getting some of the newer prints up on the blog this weekend but there's apparently some kind of a software issues between my iMac at home and my iBook at Casa Support Crew.

Hopefully I'll make it up to you later this week.

The Skipper of the Greenhorn I (who's also an EE) got me straightened out as far as what happens to the output of 12V wet cells when the power gets low.

Short version: my stooges switchboard is toast.

It's all good, all I'm out is the one sketch, I'm saving myself some hardware and the support crew is sleeping much better.

The "How to get electrocuted" in the last tag line didn't sit well.

I had planned on getting some of the newer prints up on the blog this weekend but there's apparently some kind of a software issues between my iMac at home and my iBook at Casa Support Crew.

Hopefully I'll make it up to you later this week.

Wednesday, November 4, 2009

Drawing is a chore.

I'm still turning the sketches into 1:12 drawings I can have printed.

I'm also starting to work on details like battery placement and

conduits for the wiring harness.

I had another idea that I want to bounce off the engineers.

I expect it's going to be difficult to keep the batteries charged

and if the onboard system can't keep up with the consumption on

any given day, adding more batteries really isn't going to help.

I'm thinking maybe if I were to add more batteries for ballast,

it might be helpful if I could reconfigure them.

When battery power got low, rather then run the risk of cooking off

a motor running it on voltage that's too low, I could switch from

(for instance) 6 pairs of 2 batteries to 3 pairs of 3.

The setup I had in mind is pretty simple. Picture an old fashioned

telephone switchboard from a 3 stooges flick.

I get a bunch of high amp connectors of the type they use on welding

cables, I run the leads to the ESC/motors down either side of the

battery bay with a series of female connectors in the lines.

Each battery terminal will have both a female connector and a pigtail

with a male connector that can be plugged either into the feeder

cables to the ESC/motor or into the battery next to it.

I'm also starting to work on details like battery placement and

conduits for the wiring harness.

I had another idea that I want to bounce off the engineers.

I expect it's going to be difficult to keep the batteries charged

and if the onboard system can't keep up with the consumption on

any given day, adding more batteries really isn't going to help.

I'm thinking maybe if I were to add more batteries for ballast,

it might be helpful if I could reconfigure them.

When battery power got low, rather then run the risk of cooking off

a motor running it on voltage that's too low, I could switch from

(for instance) 6 pairs of 2 batteries to 3 pairs of 3.

The setup I had in mind is pretty simple. Picture an old fashioned

telephone switchboard from a 3 stooges flick.

I get a bunch of high amp connectors of the type they use on welding

cables, I run the leads to the ESC/motors down either side of the

battery bay with a series of female connectors in the lines.

Each battery terminal will have both a female connector and a pigtail

with a male connector that can be plugged either into the feeder

cables to the ESC/motor or into the battery next to it.

Subscribe to:

Posts (Atom)